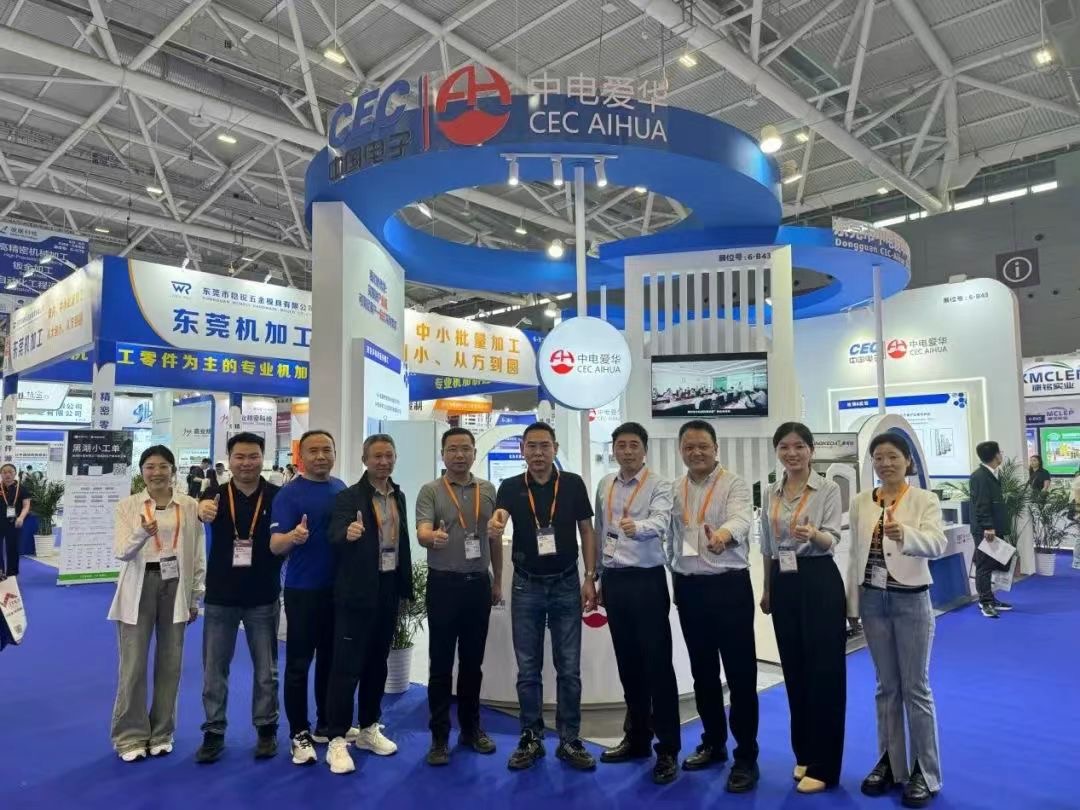

Shenzhen, March 29, 2025 - As a core enterprise in the field of high-precision machining under the China Electronics Corporation (CEC), China Electronics Corporation (CEC) today successfully completed its participation in the International Industrial Manufacturing Technology and Equipment Show (ITES Shenzhen) 2025 in Shenzhen. Ltd. (hereinafter referred to as “CLP Aihua”), as a core enterprise in the field of high-precision machining under CEC, today successfully completed its participation in ITES Shenzhen 2025. With the theme of “Precision and Innovation”, the exhibition attracted more than 1,600 exhibitors from all over the world, covering such cutting-edge fields as high-end equipment, robotics and automation solutions, precision manufacturing, etc., with more than 120,000 professional visitors. Relying on its broad industrial layout and technological advantages, CLP AIHUA demonstrated a number of core technologies and reached in-depth cooperation intentions with customers from energy, medical devices, semiconductors and other industries.

Focus on Precision Manufacturing, Leading New Trend of Industrial Upgrading

The exhibition focused on metal cutting machine tools, robotic automation equipment, industrial measurement and other high-end equipment as well as solutions for the production of precision parts and components. More than 60 activities were held during the same period, including the “Innovative Supply Chain, Driving New Growth” summit and China Medical Device Industry Development Forum, which attracted industry executives and experts from BYD, Azure, Siemens Healthcare, etc. to explore the new path of intelligent manufacturing.

The “Precision Manufacturing Theme Zone” in Hall 6, where CLP AIC is located, is the first special exhibition focusing on precision machining in China, gathering more than 200 leading precision manufacturing enterprises in South China and Japan. During the exhibition, CLP Aihua focused on displaying high-precision 5-axis machining centers, automated production line solutions and new energy automotive parts machining technology, which attracted many professional visitors.

Precise docking industry needs, fruitful customer cooperation

During the exhibition, CLP AIC received more than 200 customer inquiries, covering energy, semiconductor, medical, aviation equipment, mechanical equipment and other industries, among which nearly 20 companies, including Kefu Sea, Lance Intelligent Robotics, CGC Medical Technology, and Chuangxin Laser, expressed their strong intention to cooperate with CLP AIC. The company's technical and quality team deeply participated in the same period of activities, and Ruilman Intelligence, Lei Sai Intelligence and other enterprises to exchange core parts and components of the innovative process; with Sanqiao, Xinquanli and other automated welding solution providers to discuss intelligent production line transformation; and with the Beijing Precision Sculpture, Sanfeng Precision Instruments, and other high-end equipment enterprises to exchange high-efficiency machining solutions.

Taking the exhibition as a starting point, accelerating the layout of new tracks

During the exhibition, CLP Aiwa had in-depth exchanges with professional teams in the fields of electronics manufacturing, new energy vehicles, medical devices, etc., and gained industrial inspirations, especially in the fields of heat dissipation system requirements in the field of lasers, surface treatment processes, precision parts and components machining, and intelligent manufacturing solutions. In addition, the innovative application of magnesium alloy in lightweighting of new energy vehicles and heat dissipation structure of consumer electronics became the focus of attention, and AI-driven vision inspection system and flexible automated production line attracted much attention. Through this exhibition, CLP Aiwa will continue to optimize its products and technologies and actively promote intelligent transformation and industrial upgrading.